Production line with washing machine off line

Conveying and cleaning of line head sheet

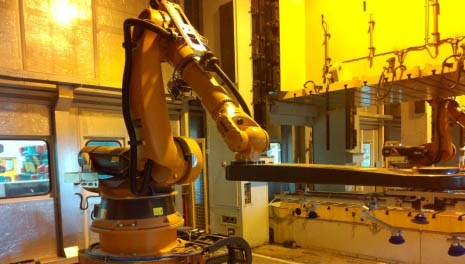

Plate transmission between lines (servo slide device)

Robot trajectory optimization

The stamping automation production line of a factory in Chang'an mainly includes: robot destacking system, double material detection system, sheet metal conveying system, sheet metal cleaning system, visual centering system, robot feeding system, inter line robot conveying system, tail blanking conveying system, whole line sealing protection and lighting system, ADC (automatic die replacement) system, control system, etc. The robot integrated external servo slide system is used to realize the plate transmission between the presses with large spacing; the whole line press is equipped with automatic clamping device to realize the ADC function, shorten the die changing time and improve the production efficiency; The automatic production line adopts the whole line sound insulation and closed protection, effectively realizes the functions of automatic equipment isolation and dust prevention, sound insulation and noise reduction, and makes the whole set of automatic production line clean, beautiful and atmospheric. The stroke times of press (single acting) slider in the automatic production line are 12 SPM, the production rhythm of medium and large stamping parts such as automobile side wall and door inner plate reaches 6 SPM, and the automatic starting rate of the whole line is ≥ 98%.