It is easy to operate, durable and reliable

45MG is an advanced ultrasonic thickness gauge with various standard measurement functions and software options. This unique instrument is compatible with all Olympus bicrystal and monocrystal thickness probes. It is an innovative instrument with all solutions in one machine and can be used in almost all thickness measurement applications.

45MG is an ultrasonic thickness gauge with various standard measurement functions and software options. This unique instrument is compatible with all Olympus bicrystal and monocrystal thickness probes. It is an innovative instrument with all solutions in one machine and can be used in almost all thickness measurement applications.

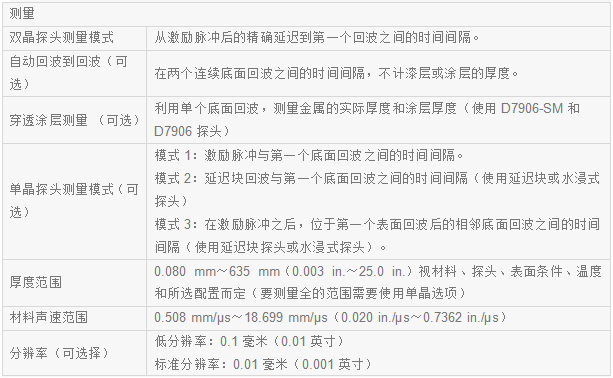

Standard function

When using the basic configuration, 45mg instrument is an easy to understand, easy to learn and easy to operate thickness gauge. After basic training, the operator can complete the commonly used thickness measurement application. However, with the addition of optional software options and probes, 45MG instrument will become an extremely thick gauge, which can be used in applications that cannot be completed by typical primary instruments. In addition, most of the options can be purchased separately at the time of purchasing the instrument, or when needed in the future.

★ Compatible with all Olympus bicrystal probes, it can measure the thickness of internal corroded metal

★ Low / high value mode

★ Two alarm modes

★ Difference mode

★ Time base B scan

★ Reduction rate

★ Gain adjustment (standard, high, low)

★ Password instrument locking

45mg instrument with optional rubber cover and bracket

Ability to withstand harsh environments

★ Strong and durable, the design conforms to IP67 standard.

★ Explosive atmosphere: it can operate safely in the explosive atmosphere environment specified in NFPA 70, section 500, Division I, Division 2, group D, and has passed the test specified in mil-std-810g method 511.4 procedure I.

★ Anti collision test: passed the test specified in procedure I of mil-std-810g method 516.5, 6 cycles per axis, 15 g, 11 msec half sine wave.

★ Anti vibration test: passed the test in Figure 6, Appendix C, procedure I, mil-std-810g method 514.5, general exposure: 1 hour per axle.

★ Wide operating temperature range

★ Optional rubber sleeve with bracket

Simple and easy to operate design concept

★ Simple keyboard area that can be operated by right hand or left hand only

★ Easy to access most functions directly

★ Storage mode using built-in microSD memory card and pluggable microSD memory card

★ USB communication port

★ Optional alphanumeric data recorder with 475000 thickness readings or 20000 waveforms

★ Default or custom single crystal probe settings (optional)

★ Instrument locking with password protection

★ Color transparent QVGA display, with indoor and outdoor color settings, with clarity

Optional Features

With just a few keystrokes, it can transform from simple corrosion thickness gauge to multi-function thickness gauge. 45mg thickness gauge provides 5 software options that need password activation, so it is one of the most widely used thickness gauges in the industrial field.

Echo to echo / through coating: using the echo to echo option, the actual thickness of the metal will be displayed on the instrument screen, while the thickness of the coating will be ignored. The through coating option measures the thickness of metallic and non-metallic coatings, both of which are adjusted for their respective sound velocity values. Therefore, it is not necessary to remove the paint layer or coating on the material surface during thickness measurement.

Single crystal: this option can measure the thickness of many materials, such as metals, plastics, composites, glass and ceramics. This option is compatible with single crystal MICROSCAN probes in the range of 2.25 MHz to 30 MHz.

Single crystal high penetration: this option allows thickness measurement of thicker or more attenuating materials, such as glass fiber or cast metal. Compatible with single crystal MICROSCAN probes in the range of 0.5 MHz to 30 MHz. This option contains single crystal options.

Data recorder: 45mg thickness gauge is equipped with a fully functional built-in bidirectional alphanumeric data recorder, which can conveniently store and transmit thickness reading and waveform data. This option contains the windows based gageview interface program.

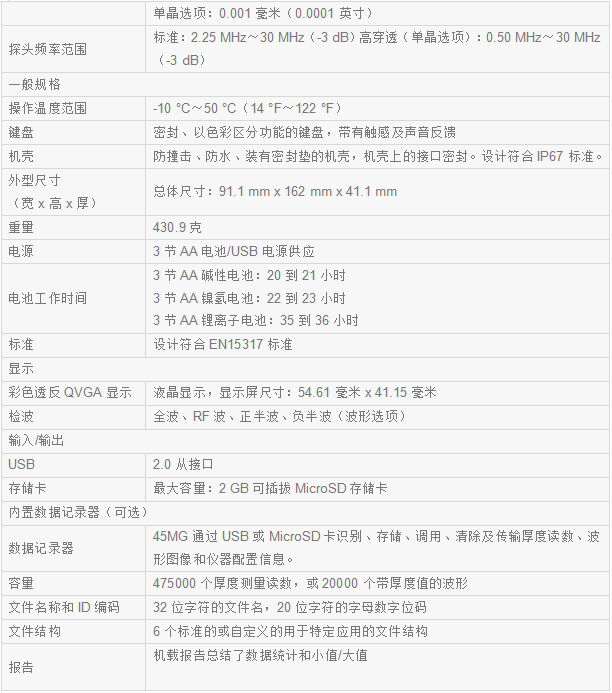

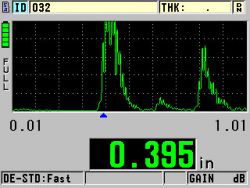

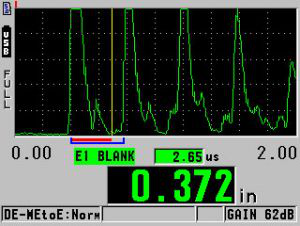

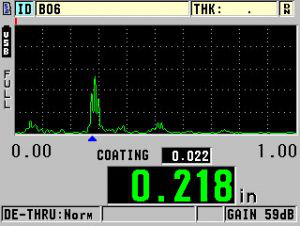

Real time A-scan with waveform adjustment function: with this optional real-time A-scan mode, users can directly view the ultrasonic waveform (or A-scan) on the display screen of the thickness gauge, check the thickness measurement readings, and manually adjust the gain and blank settings, so as to greatly enhance the measurement performance in challenging applications. This extremely useful option includes manual gain adjustment, extended blank, first echo blank, range and delay parameters.

Indoor display settings, optional A-scan mode

Outdoor display settings, optional a scan mode

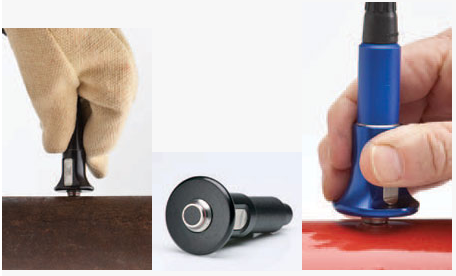

Using double crystal probe to measure corrosion workpiece

One of the main applications of 45MG thickness gauge is to measure the residual thickness of corroded or corroded pipes, pipe fittings, boxes, pressure vessels, hull shells and other structures. The double crystal probe is often used in these applications.

★ Automatic probe identification function for standard d79x series double crystal probe

★ When double echo occurs during calibration, double echo warning will be issued

★ The echo to echo / through coating option measures surfaces with paint and coatings

★ High temperature measurement: up to 500 ° C

B-scan imaging (time based)

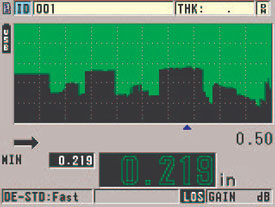

The B-scan function provided by 45mg instrument can convert real-time thickness reading into cross-section image on screen. This standard function is very useful for observing the change of material thickness over a certain distance. As soon as the probe touches the surface of the material, B-scan is activated. The freezing small value function is used to display the small thickness value of the scanning area. The optional 45mg data recorder can store more than 10000 thickness readings in a single B-scan.

Indoor display setting, B-scan mode

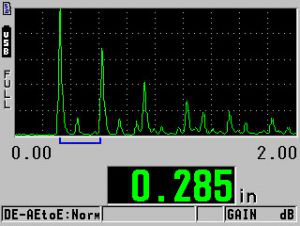

Echo to echo / through coating options

Echo to echo

The thickness gauge uses multiple bottom echoes to display the actual metal thickness regardless of coating thickness:

★ Auto echo to echo

★ Manual echo to echo (only in A-scan option), the following operations can be performed:

? Gain adjustment

? Extended blanks

? Echo blank

Display the automatic echo to echo mode of a scan

Adjust the manual echo of the first echo blank to echo mode

High temperature surface

45MG thickness gauge with d932 series probes (D790, d790-sm, d790-rl and d790-sl) is an ideal choice for measuring high temperature materials (up to 500 ° C), and can obtain stable thickness readings. The zero position compensation function of 45mg improves the accuracy of measurement on high temperature surface by compensating the temperature change of probe delay block due to thermal drift.

Penetration coating technology

The actual thickness of the metal is measured using a single bottom echo. Using this technique, the thickness of the metal and coating can be shown separately. These two thicknesses are adjusted according to the sound velocity values of their respective materials. Therefore, to obtain the thickness of the metal, it is not necessary to remove the paint and coating from the surface. D7906-sm, d7906-rm and d7908 bicrystal probes are used in the penetration coating measurement technology.

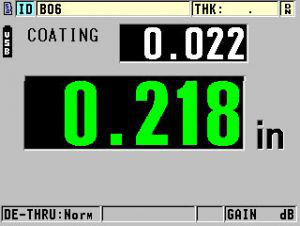

Through coating mode showing coating thickness and steel material thickness (waveform option not activated)

Through coating mode showing optional waveforms

Using single crystal probe to measure workpiece accurately

Measure the thickness of plastics, metals, composites, glass, rubber and ceramics

Using single crystal probe

Users can measure the thickness of metal, plastic, composite, glass, ceramic and other materials with single crystal probe. We offer single crystal probes of various frequencies, diameters and connector types. If you want to use 45mg instrument with single crystal probe, you must purchase single crystal software or high penetration software option.

★ When using single crystal probes in the frequency range of 2.25 MHz to 30 MHz, the single crystal software option displays measurements with a resolution of up to 0.001 mm (0.0001 in).

★ The high penetration software option is used to measure high attenuation materials such as glass fiber, rubber and thick castings.

★ Measure thickness, sound velocity or transit time.

★ The function of automatically calling the default settings and custom settings for the current application simplifies the thickness measurement operation.

Single crystal software options

With the single crystal software option, the user can complete extremely thick measurement with resolution up to 0.001 mm or 0.0001 inch. This option is compatible with single crystal MICROSCAN probes in the range of 2.25 MHz to 30 MHz.

★ Most thin and thick materials

★ Plastic bottles, pipe fittings, pipes and sheet materials with wall thickness of 0.08 mm (0.003 inch)

★ Metal containers, ring plates, machined parts with wall thickness of 0.10 mm (0.004 inch)

★ Cylinder bore, turbine blade

★ Glass bulb, bottle

★ Thin walled glass fiber, rubber, ceramics and composites

★ Container with small radius of curved surface or fillet

High penetration software option can measure many casting metal parts and materials with strong acoustic attenuation.

Application settings call

The operation of thickness measurement is simplified by using the function of setting and calling. After the user selects any storage probe, the 45mg thickness gauge will call out all the parameters related to the built-in probe.

Standard settings for storage

The 45MG instrument has 21 standard single crystal probe settings, which can be used for common measurement operations. These default probe settings are available for a wide variety of thickness measurement applications.

Stored custom settings

The 45MG can also store the settings of 35 custom single crystal probes, including calibration information. The user can connect the appropriate probe and call the setting file, then the instrument can measure the thickness, and even complete complex thickness measurement applications.

Sound velocity measurement of materials

45MG instrument can measure the sound velocity of material. This standard function is very useful in applications where sound velocity of materials is closely related to other properties. Typical applications include monitoring the degree of spheroidization of cast metals and monitoring the density change of composites / glass fibers.

Reduction measurement

Difference mode and reduction mode are the standard functions of 45mg. The difference mode shows the difference between the actual thickness and the preset thickness. The reduction rate calculates and displays the percentage of thickness reduction after the material thickness becomes thinner. A typical application is to measure the reduction of a sheet steel that has been bent and deformed and will be made into a body panel.

Use a 20 MHz delay block probe to measure thin plastic materials.

The thin glass was measured by v260-sm sonopen probe.

Measure the thin condition of the metal plate due to bending deformation.

It can measure the thickness of many materials including plastic, metal, rubber, glass, ceramic and composite materials.

Single crystal high penetration software options

With this option, users can measure thick or sound attenuation materials such as rubber, glass fiber, casting and composite materials with low frequency single crystal probe (as low as 0.5 MHz). This option contains single crystal options.

★ Most of the thicker or stronger sound attenuation materials

★ Thick cast metal parts

★ Thick rubber tire and track

★ Fiberglass hull, storage tank

★ Composite board

★ 0.01 mm (0.001 in) resolution for probes in the frequency range of 0.5 MH to 1.0 MHz